MATERIAL HANDLING | |

KRANKO OVERHEAD KRANE | 15/5 TON CAPABILITIES |

OMI OVERHEAD CRANE | 25/5 TON CAPABILITIES |

FORKLIFTS WITH CAPABILITIES TO | 10,000 LBSS |

MACHINING | |

2-CNC UNIVERSAL HEAD PLANER TYPE MILL | X39’6″ Y79″ Z 42″ W/28 TON LOAD CAPACITY |

BUTLER NEWALL ELGAMILL-MANUAL | X167″ Y67″ Z38″ |

CNC KITAMURA MYCENTER 5 MACHINING CENTER | X44″ Y22″ Z24″ |

CNC KITAMURA MYCENTER 3 MACHINING CENTER | X32″ Y19″ Z21″ |

CNC KITAMURA MYCENTER O MACHINING CENTER | X12″ Y14″ Z10″ 10,000 RPM |

BRIDGEPORT MILLS WITH DIGITAL READOUTS | |

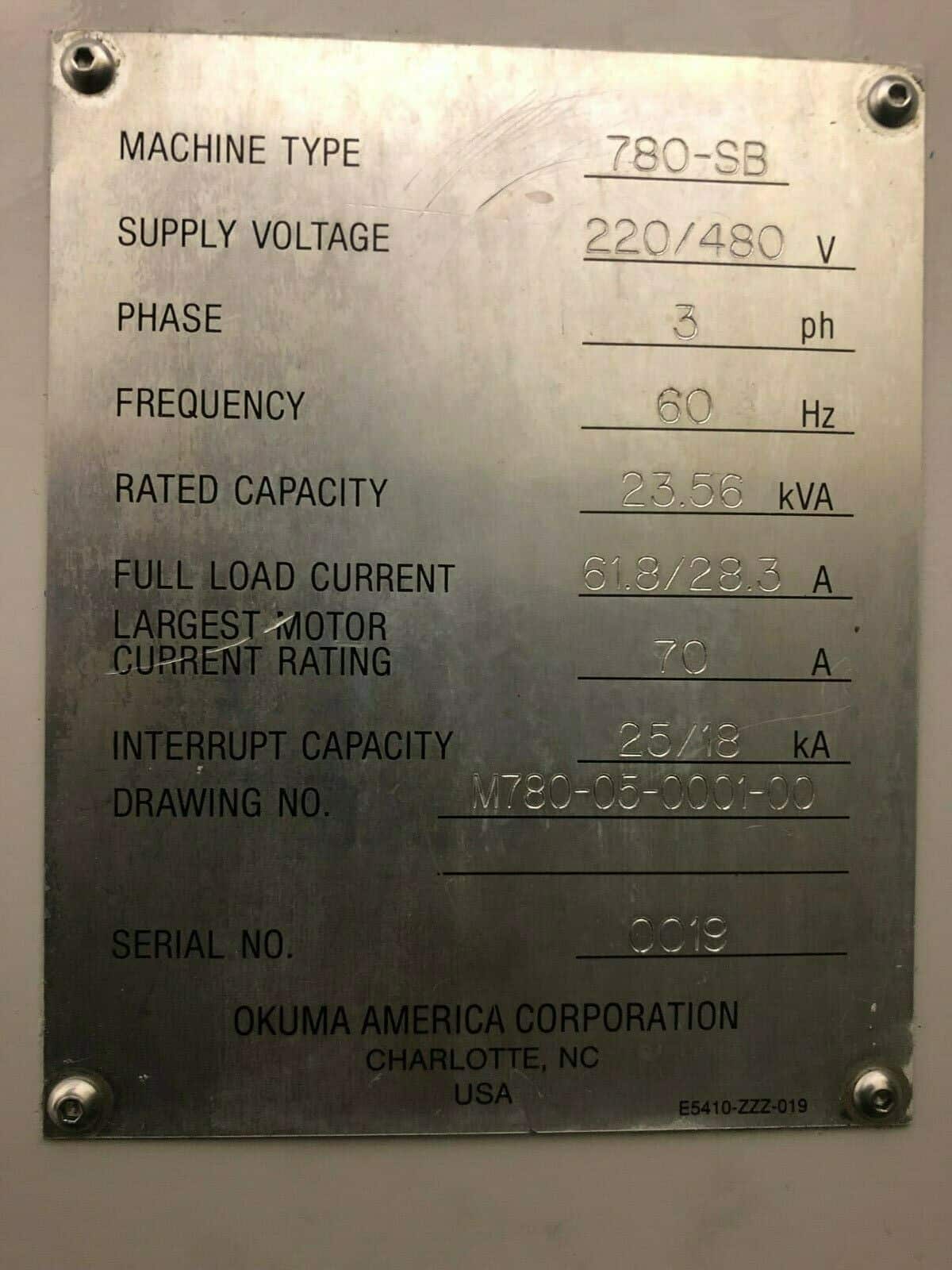

CNC OKUMA LB45 TURNING CENTER | 26″ SWING X 40″ LENGTH |

CNC OKUMA CROWN TURNING CENTER | 15.5″ SWING X 28″ LENGTH |

CNC OKUMA LB1420 TURNING CENTER | 14″ SWING X 25″ LENGTH |

2 X CNC OKUMA LB35 TURNING CENTER | 20″ SWING X 30″ LENGTH |

CNC OKUMA LU45 TURNING CENTER (TWIN TURRET) | |

TOOLMEX LATHE | 28″ SWING X 157″ LENGTH |

POREBA LATHE (GAP BED) | 48″ SWINGS X 157″ LENGTH |

LATHES WITH CAPACITIES TO | 32″ SWING X 120″ LENGTH |

SURFACE GRINDERS WITH CAPACITIES TO | 12″ X 24″ |

CNC NICOLAS CORREA BRIDGEMILL | X139″ Y79″ Z31″ |

CNC NICOLAS CORREA UNI HEAD PLANNER TYPE MILL | X168″ Y59″ Z47″ |

CHEVALIER CNC KNEE MILL | |

COMPLETE SAW SERVICE | |

CLAUSING MILL WITH PROTOTRAK CONTROL | |

CHEVALIER MILL WITH ACU-RITE MILLPWR CONTROL | |

MORI SIEKI MV-JR VERTICAL MACHINING CENTER | |

OKUMA MULTUS B300-W | (5 AXIS) |

OKUMA CAPTAIN L370M | (MILLTURN) |

OKUMA MC-V4020 | |

FABRICATION | |

WELDING MACHINES INCLUDE: | FULL FABRICATION CAPABILITIES |

PRESS BRAKE | SHEAR – ¼” THICKNESS, 10′ LENGTH |

QUALITY CONTROL | |

MITUTOYO CMM CRYSTA APEXC 9106 | X905mm Y1005mm Z605mm |

BROWN & SHARP MICROHEIGHT | QUALITY DEPARTMENT DESIGNED TO INSURE |

AFTER REVIEWING OUR HIGHLIGHTS WE THINK YOU WILL AGREE… | |

Okuma leads the industry with reliable, accurate lathes ranging from affordable, feature-packed entry-level machines to multi-axis, high speed, high-precision, high performance turning centers. Whatever your application, Okuma can tailor a lathe to meet your specific needs with a wide variety of bore sizes and work envelopes, as well as other. Okuma Lathe Captain L370M #2; Okuma Genos L300-MW Lathe #1; Okuma Genos L300-MW Lathe #2; Okuma Genos L250E; Brother TC-R2B Vertical Machining Center.

Laser

- Amada Ensis 3015 AJ 6K Fiber Laser

- 60” X 120” Table

- CL Automation

- Amada LCG 3015 AJ 6K Fiber Laser

- 60” X 120” Table

- Amada LCG 3015 AJ 4K Fiber Laser

- 60” X 120” Table

Fabrication

- Press Brake

- Accurpress Accell 417510, 175 TON, 10ft

- Accurpress Accell 425012, 250 TON, 12ft

- Welding

- Miller CP-302

- Miller Deltaweld 452

- Miller Syncrowave 250

- Miller Deltaweld 302

- Miller Dynasty 280

- Miller Millermatic 252

- Hypertherm Powermax 1650 Plasma Cutter

- (2) 4’ X 8’ Strong Hand Weld Table

Waterjet

- Omax 60120

- 60” X 120” Table

- Cut any material up 6” thick

CNC Milling

- (5) Okuma Genos M560-V

- 41.34” x 22.05” x 18.11” Max machining volume

- 900 lbs table capacity

- (1) 5-axis milling capabilities

- Okuma Millac 1052V

- 80.71” x 41.73” x 31.50” of travel

- 5,511 Max table load

- Mori Seiki MV-80

- 80” x 32.05” x 29.53” of travel

- 6,600 lbs max table load

- Toshiba BP-110.P20 Boring Mill

- 100” (X), 65” (Y), 45” (Z), 20” (W)

- 40,000 lbs max table load

CNC Turning

- Okuma Multis U3000 9-axis turning center

- Okuma LB 35 II

- Okuma Genos L300E-M

- Okuma Captain L470

- Okuma Captain 70

- Okuma Captain L370M

- Okuma Cadet L1420

- Mazak Quick Turn Nexus 450-II MY

- 12.3” (X), 124.8” (Z), 116.14” (W)

- Max Swing 33.27”

Stamping

- Komatsu E2G400U

- 440 Ton

- 49” x 99” Bolster

- Perfect

- Feeder

- DEES Hydraulic

- 400 Ton

- 47” x 137” Bolster

- Komatsu OBW200

- 220 Ton

- 33.5” x 95” Bolster

- Minster Feeder

- Stamtec G1-110

- 121 ton

- 23.6” x 45.25” Bolster

- CWP Feeder

- Seyi Mark 2-121-W

- 121 ton

- 26.8” x 45.3” Bolster

- AIDA 80

- 88 Ton

- 18.1' x 37.4' Bolster

- Air-Hydraulics 50

- 50 Ton

- Press Master 50 ton Hydraulic

EDM

- (2) Mitsubishi FA 20S

- Mitsubishi FA

- Mitsubishi FX 20K

- Mitsubishi M25K

- Agie CNC Drilling

Surface Grinding

- Blanchard Grinder

- 120' Corner to corner, 48' height, and 15,000lbs capacity

- Okamot

- 16-32

- Okamot

- 12-24

- (2) Okamot

- ACC 6-18 DX3

- Okamot

- 6-18 Linear

Manual Machining

- Trax DPM5 (CNC controls)

- (5) Acer E-mill

- Lagun Knee Mill

- Brown & Sharpe No. 3B Plain

- Clausing-Metosa C2087SS Lathe

- Clausing-Metosa C1565VS Lathe

- Harding Tool Room Lathe

- (2) Sharp RD-1600 Radial Arm Drill

- Ikeda Radial Arm Drill

- (2) Clausing 20 Drill Press

Part Prep

- (2) Swec

- FMD-3LR Vibratory Tumbler

- D

- ALL C-916 Saw

- Crob Band Saw

- Marvel Series 8 Mark III Band Saw

- Sand Blast Cabinet

- Parts Cleaning Tub

- (4) pedestal Grinders

- (2) Disk Grinders

- Jet 6”x48” & 12” Disk Machine

Manual Mills

- (3) Lagun FTV-2, Travels 10” x 50”

- (2) Acer E-Mill, Travels 10” x 50”

- (2) Clausing Atlas, Travels 10” x 50”

Drill Presses

- (2) Sharp RD-1600, 16” Column, 4’ Arm

- Ikeda RM-1000, 10” Column, 3’ Arm

- (2) Clausing 20

Heat Treat

- (3) Cress Heat Treat Ovens

- Gruenberg Oven

- Rockwell Hardness Tester

Marking

- Keyence 50-Watt fiber marking/engraving laser

Miscellaneous

- (2) Sullair 3700 Compressors

- Brecknell 10,000 lbs Scale

Lifts

- CAT GC70K-LP

- 15,000 lbs

- Clark CGC 70

- 15,000 lbs

- CAT P5000-LP

- 4,500 lbs

- CAT GC 20

- 4,000 lbs

- CAT GC25K

- 5,000 lbs

Crain

- (2) Overhead

- 7.5 ton

- Overhead

- 5 ton

- (10) Overhead

- .5 – 2 ton

Quality Control/Reverse Engineering

- Zeiss Condura G2

- 6’ Far Arm Edge

- 6’ Far Arm Platinum

- Micro-Vu Optical Comparator

Computer Workstations

- (4) Engineering

- (7) Programming

Okuma Lathe Captain L370m Parts Manual Diagram

Software

Okuma Lathe Captain L370m Parts Manual 2017

- Solidworks

- Logopress

- AutoCad

- Esprit

- Pep

- Omax Make

- Zeiss Calypso

Okuma Lathe Captain L370m Parts Manual Youtube

Trucking

- Freightliner with box trailer

- 44,000 lbs

- Ford F750 Flatbed

- 17,800 lbs

- (2) 1 Ton Flatbed

- 6,000 lbs

- 20,000 lbs with trailer

- ¾ Ton

- 3,000 lbs